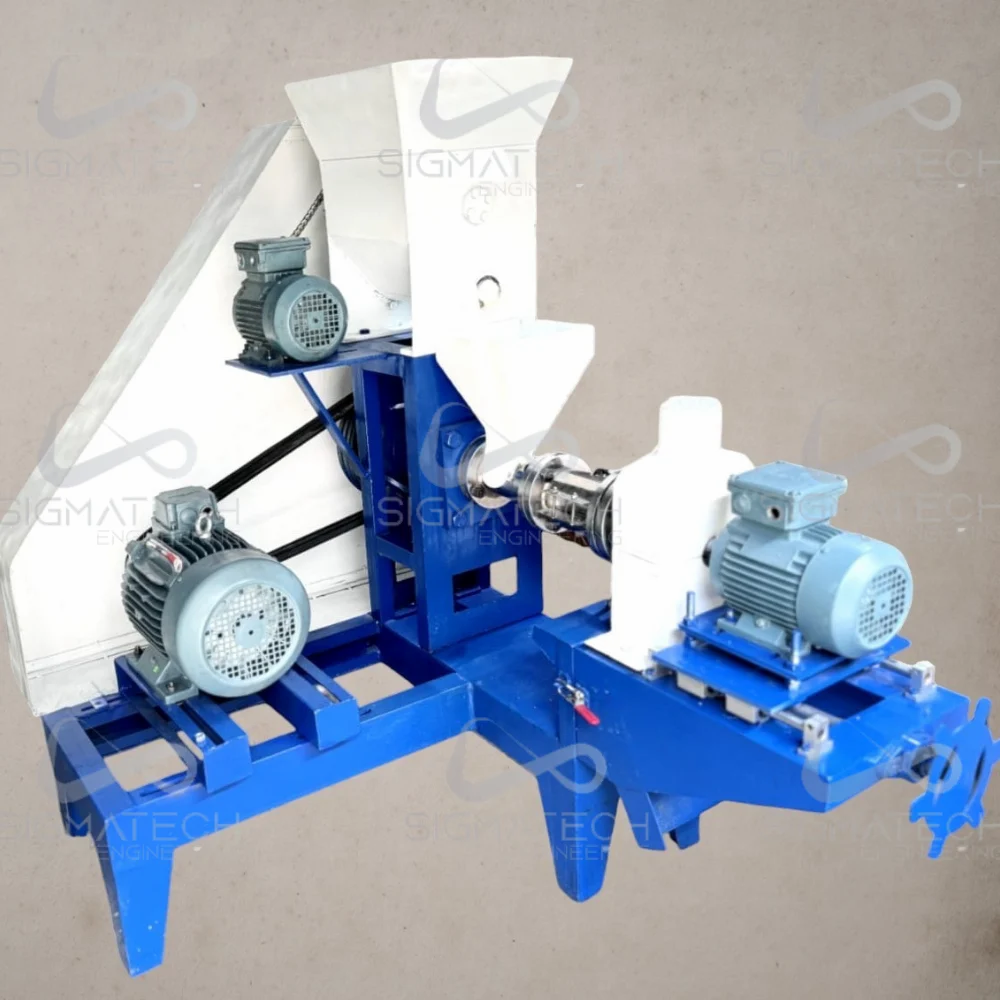

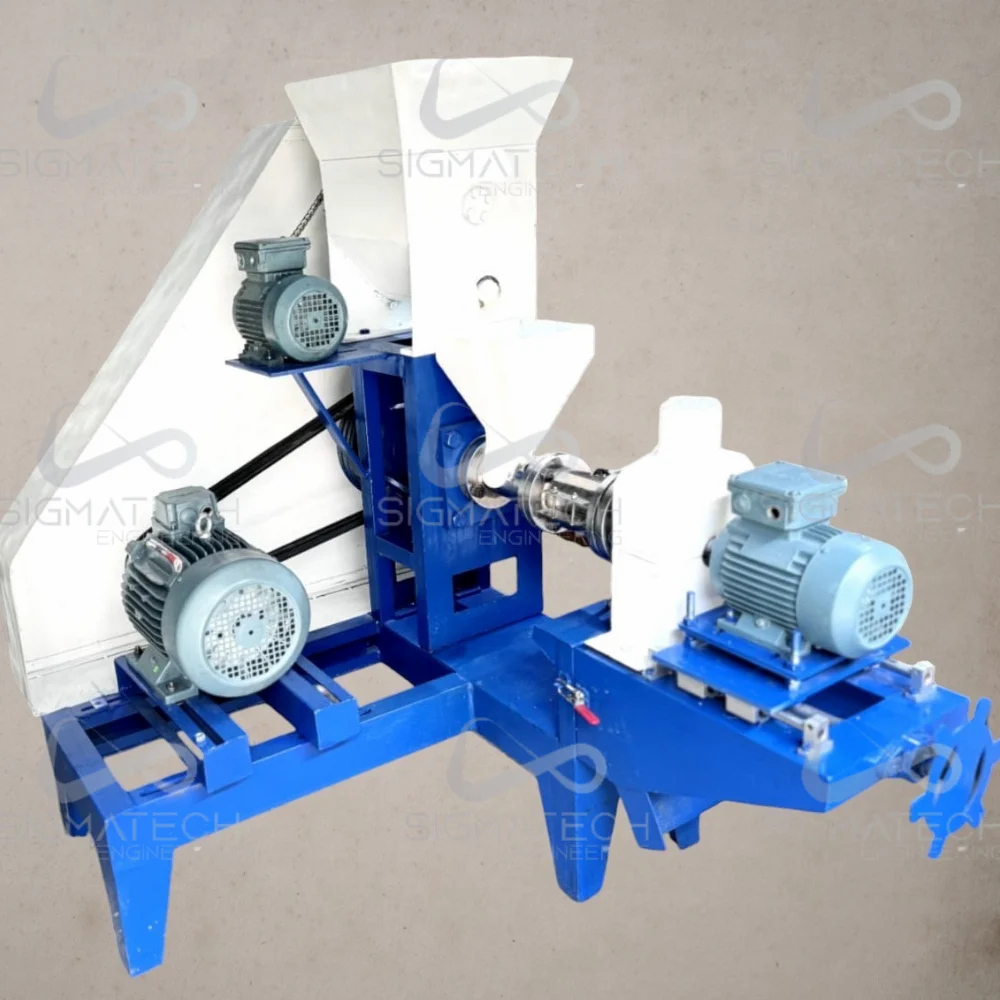

Industrial Cattle Feed Plant

Industrial Cattle Feed Plant Specification

- Country Of Origin

- India

- Frequency

- 50 Hertz (HZ)

- Material

- Metal

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Warranty

- Yes

- Features

- High Quality

Industrial Cattle Feed Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Industrial Cattle Feed Plant

- Capacity:- 200-250 kg/hr

- MOC :- MS

- Total Power :- 18 HP

-

An industrial cattle feed plant is a facility that automates the process of grinding, mixing, and pelletizing various grains, proteins, vitamins, and minerals into consistent, nutritious feed for livestock, using computerized systems (PLC/SCADA) for precise ingredient measurement, automated batching, and quality control, often with high-capacity storage and advanced bagging for efficiency and record-keeping.Key Components & Process:

- Raw Material Handling: Ingredients (corn, sorghum, soy, minerals, molasses) are stored in bins, then transported (often via elevators) to the processing area, with sensors ensuring correct flow.

- Grinding/Pulverizing: Materials are broken down to a uniform particle size using hammer mills or disintegrators.

- Batching & Mixing: Computer-controlled systems (PLC/SCADA) accurately weigh and combine ingredients according to specific recipes, adding vitamins, minerals, and binders.

- Pelletizing (Optional): The mixed mash is often extruded and compressed into uniform pellets for easier consumption and storage, sometimes with a cooling process.

- Quality Control & Packaging: Metal detectors check for contaminants, and the final product is bagged automatically, with systems tracking inventory and production.

Key Features:- Automation: Fully or semi-automatic systems with PLC/SCADA for precision and minimal labor.

- Accuracy: High accuracy in batching (e.g., 2%) ensures consistent nutritional value.

- Capacity: Plants range from smaller mobile units to large industrial setups.

- Technology: Use of sensors, control panels, and data logging for monitoring and control.

Benefits:- Consistency: Uniform feed quality ensures optimal animal nutrition.

- Efficiency: High-speed processing and automated bagging reduce labor costs.

- Traceability: Complete records of raw materials and finished feed.

In essence, an industrial feed plant transforms raw agricultural products into precisely formulated, convenient feed through a streamlined, automated manufacturing process.-

Fully Automatic Cattle Feed Plant Manufacturer from KhannaComputerized Cattle Feed Plant is designed from durable and strong bins for storing diverse ingredients. This is designed with a m...namdhariindustrialworks.com

-

Latest Fully Automatic Cattle Feed Plant | 200 TPD27 Jun 2025 every day begins with the receipt of essential raw materials maize soybean deoiled cake wheat bran molasses and micronu...YouTubeCremach Pvt. Ltd.1m

-

CATTLE FEED PLANT WITH LATEST TECHNOLOGY1 Jul 2022 grinding section premixer above hammer mill for better efficiency and grinding of fibrous material hammer mill patented ...YouTubeLark Engineering4m

Show all

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free