Automatic Flour Mill Plant

Automatic Flour Mill Plant Specification

- Surface Finish

- Coated

Automatic Flour Mill Plant Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 15 Per Month

- Delivery Time

- 35 Days

- Main Domestic Market

- All India

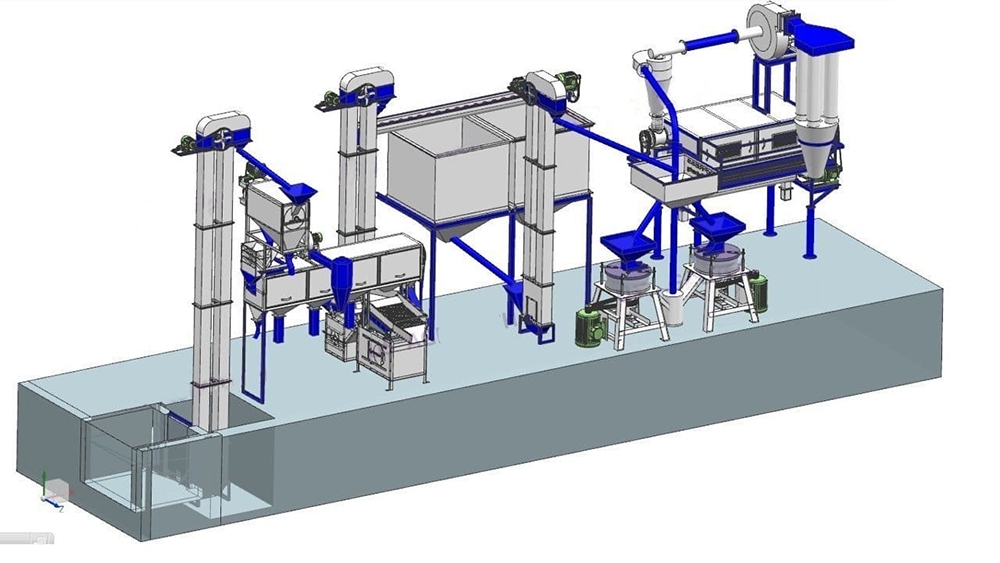

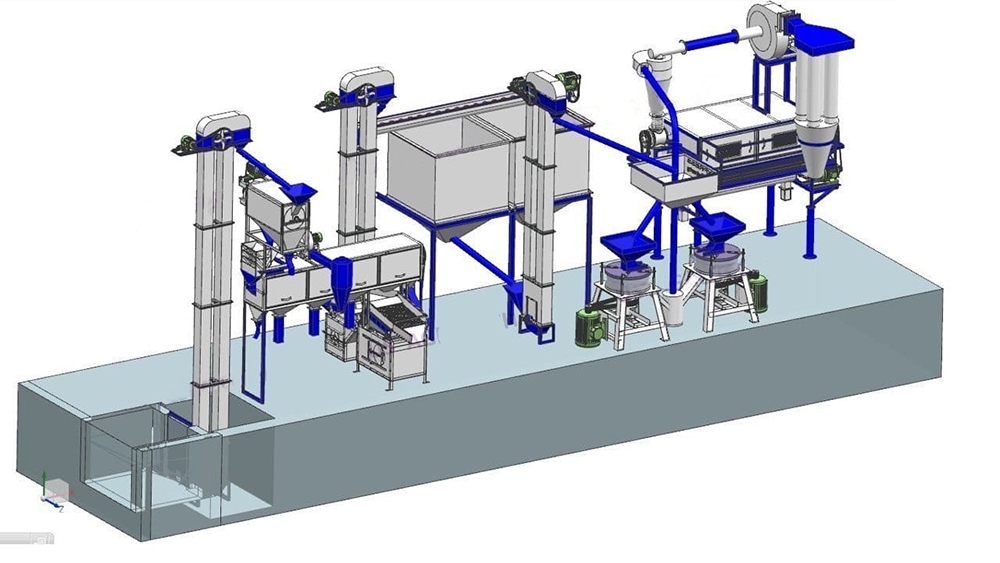

About Automatic Flour Mill Plant

An Automatic Flour Mill Plant is

a high-efficiency, integrated system that automates the entire grain-to-flour process, from cleaning and grinding to sieving and packaging, reducing manual labor, ensuring consistent quality, and improving hygiene through automated handling and processing. These plants use advanced technology like roller mills, destoners, and dust collectors, often with PLC controls, to process various grains into fine flour with minimal human intervention, making them ideal for commercial production. Key Components & Process

- Cleaning: Grains are first cleaned using magnetic selectors, scourers, and destoners to remove impurities like metal, stones, and dust.

- Tempering: Moisture is adjusted to optimal levels for milling.

- Milling: Pneumatic roller mills grind the tempered grain, separating bran, germ, and endosperm.

- Sieving/Purification: Plansifters and rotary sieves separate the ground material into different flour grades (like whole wheat, semolina).

- Blending: Different flour streams can be blended for specific products.

- Packaging: Final flour is automatically weighed and packed.

Key Features & Benefits

- High Automation: Operates with little human interference, increasing productivity.

- Versatility: Can handle wheat, rice, corn, and other grains.

- Cost-Effective: Reduces labor costs and energy consumption through optimized power usage.

- Compact Design: Many systems are designed for easy installation in smaller spaces.

- Quality & Hygiene: Ensures consistent particle size and maintains high hygiene standards.

How it Works (Simplified Flow)

- Input: Grains enter the system.

- Purification: Magnetic selectors, destoners, and scourers remove contaminants.

- Milling: Roller mills grind the grain with friction and pressure.

- Sifting: Sieves and plansifters separate particles.

- Output: Desired flour is produced.

-

Industrial Atta Chakki PlantAn Automatic Atta Chakki Plant is a fully automated flour milling system designed for high efficiency and productivity. It include...tulsiagrofood.com

-

Fully Automatic Flour Mill Plant | Swarn & Co. - TradeindiaProduct Overview. Key Features. Fully Automatic Flour Mill Plant grants modern performance and accuracy of flour processing. It he...Tradeindia

Price 500000.0 INR/ Number

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 15 Per Month

- Delivery Time

- 35 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free