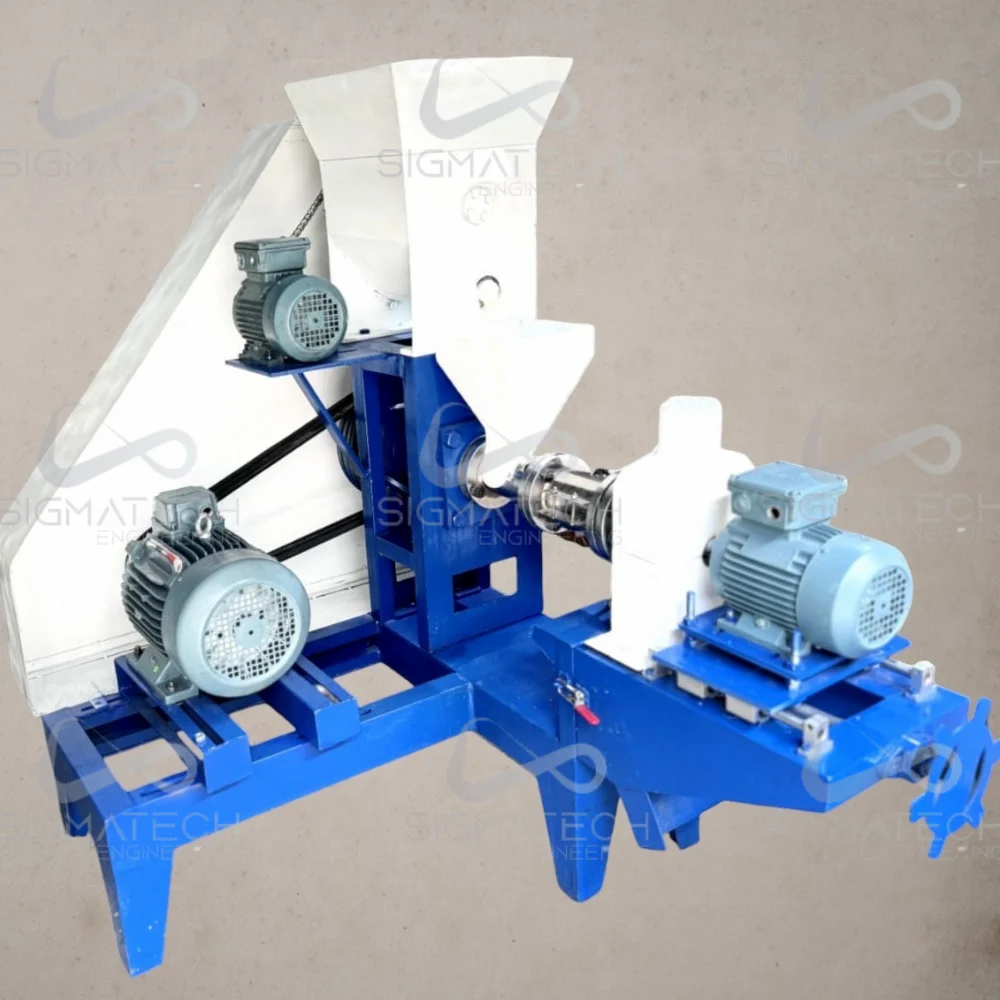

Automatic Cattle Feed Ring Die

Automatic Cattle Feed Ring Die Specification

- Power Source

- Electric

- Features

- High Quality

- General Use

- Industrial

- Automatic

- Yes

- Voltage

- 220-440 Volt (v)

- Feature

- Lower Energy Consumption

- Warranty

- Yes

Automatic Cattle Feed Ring Die Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Automatic Cattle Feed Ring Die

- MOC :- MS

- Capacity:- 900-1000 kg/hr

An Automatic Cattle Feed Ring Die is the core component in industrial machines that transform ground feed ingredients (grains, brans, proteins) into dense, uniform, nutrient-rich pellets for livestock, using high-pressure rollers to force material through precisely sized holes in a rotating ring die, ensuring consistent quality, improved digestibility, and efficient animal feeding at large scales.

Key Components & Function

- Ring Die: A heavy, rotating metal ring with many small, cylindrical holes (dies) that shape the feed into pellets.

- Rollers: Fixed or rotating rollers press the conditioned feed material against the inside surface of the rotating ring die.

- Conditioner: Steam and moisture are added to the ground feed (mash) before entering the die, which gelatinizes starches and modifies proteins, improving pellet quality and digestibility.

- Feeder & Motor: A variable speed motor controls the feed rate, while a powerful drive system (often V-belt) rotates the die and rollers.

How it Works (Pelletizing Process)

- Conditioning: Raw feed mash is mixed with steam in the conditioner for better binding and nutrient absorption.

- Compression: The conditioned mash is forced into the ring die by rollers.

- Extrusion: The high pressure forces the mash through the die holes, forming dense, cylindrical pellets.

- Cutting: A cutter blade slices the extruded pellets to the desired length as they exit the die.

Benefits for Cattle Feed

- Improved Nutrition: Pelleting increases nutrient utilization and reduces feed waste.

- Consistent Quality: Produces uniform pellets in size, shape, and density.

- High Capacity: Ideal for large-scale commercial operations (2-20 tons/hour).

- Efficiency: Reduces energy consumption and lowers maintenance costs.

-

Ring Die Animal Feed Pellet Machine15 Oct 2018 Ring Die Animal Feed Pellet Machine Overview A Ring Die Feed Pellet Machine is an advanced pelletizing machine used in ...www.feedpelletizer.com

-

High Efficiency Ring Die Feed Pellet Mil with Capacity of 2-20t/hIntroduction to Ring Die Feed Pellet Mill. Ring die feed pellet machine is designed for making crushed raw material into feed pell...tondepelletmill.com

-

Ring Die Animal Feed Pellet MillIt adopts fully stainless steel conditioner and large open access door for convenient maintenance. Inside the conditioner, there a...www.feedpelletplants.com

Show all

Price 100000.0 INR/ Number

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 10 Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free